The Terminailer all but shatters the stereotypical myth that sub-component equipment is essentially peripheral – unimportant. And it does so by quickly and accurately driving far more framing nails in your wall panel jobs than ever before. Whether in your shop or in the field, one operator sets the pace for production and quality, which reduces labor costs and other aspects of overhead.

The new Terminailer V.8 improves on the previous generation Terminailer in several key ways:

All new HMI/Software

• Siemens Pivoting HMI Touchscreen display to operate from either side

• On-screen tutorial for all menu items

• Operator now controls functions such as process speed, nail spacing, nail patterns, etc.

• Simplified input commands

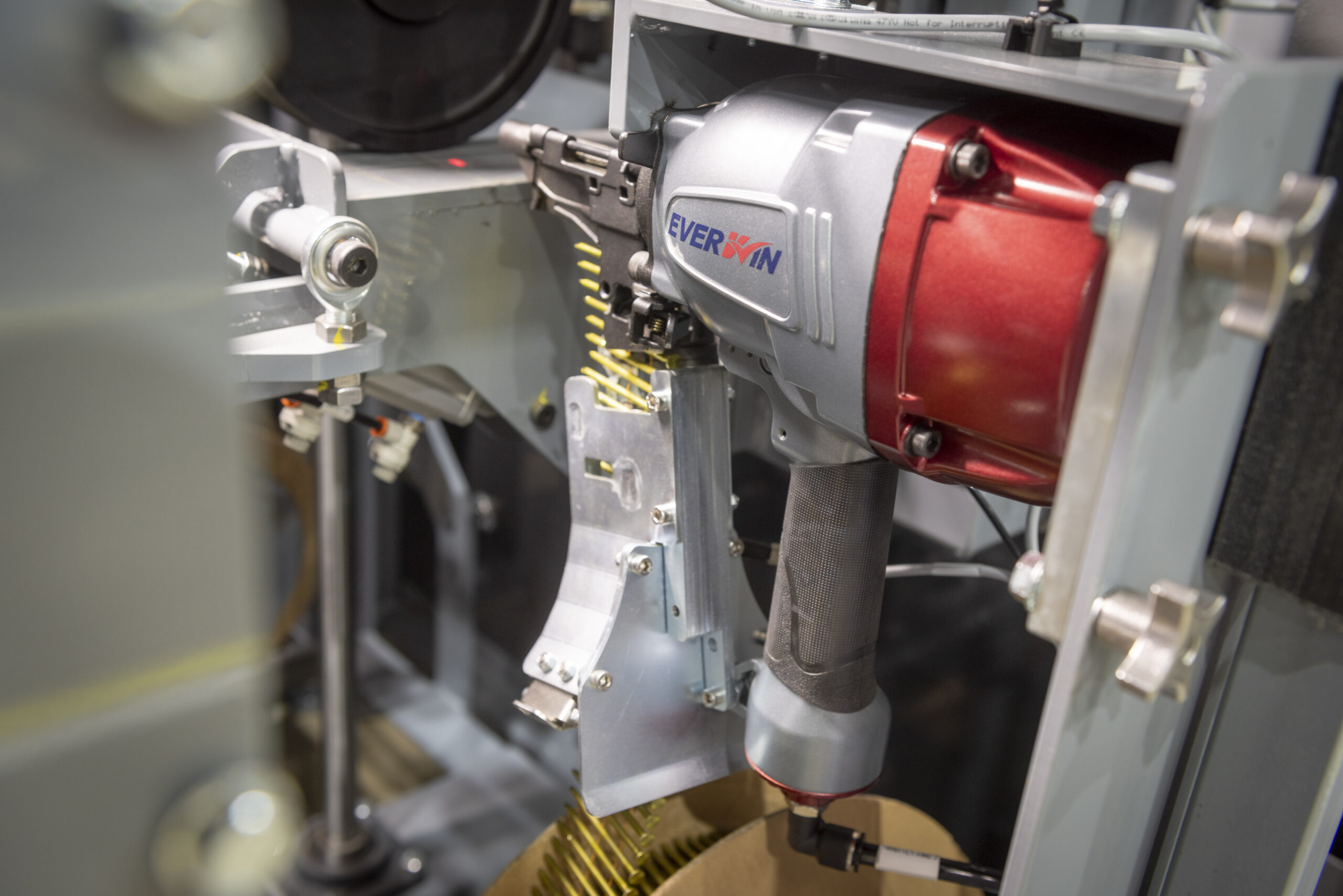

Nail Feed Complete Redesign

• All new frame to allow for redesigned nail coil placement with direct feed path

• EverWin PN90-PAL industrial tools now standard equipment

• New nail guides with spring-loaded tensioners

• Nail coils move with vertical travel of the nail guns

Reengineered air system

• SMC “Soft–Start” Pneumatics

• Simplified air for control to all components: lift–cylinders, triggers, stop–gate, etc.

• Direct air supply to each nail gun for improved nailing performance

• All pneumatic elements are clearly labeled for EZ service and adjustment

Overall Features

• Pharmaceutical grade assembly, industrial grade durability

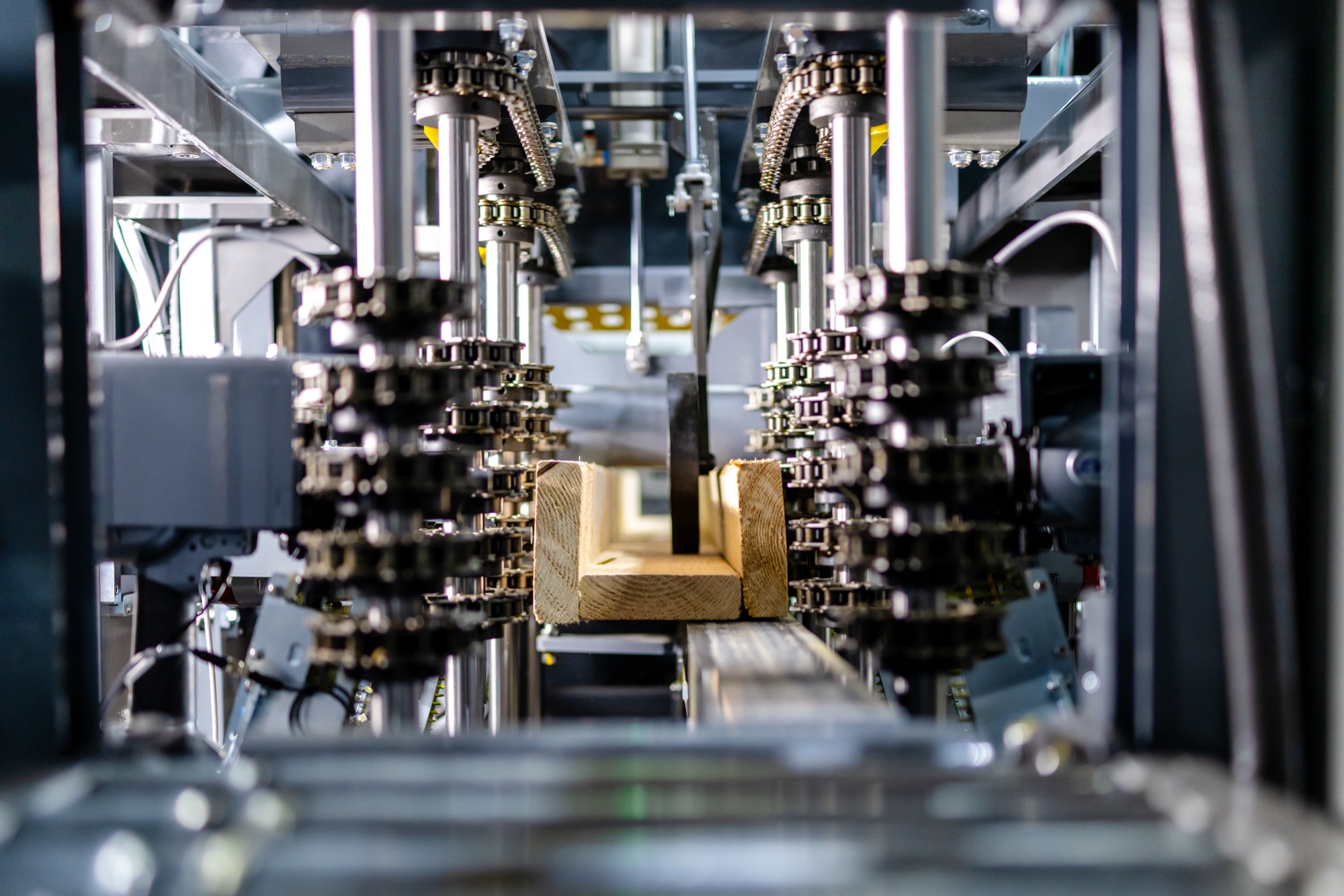

• “Block–wheel” redesign for 3X increased applied force

• Approximately 1,200# of applied clamping force resulting in straighter finished

sub–components from even the poorest lumber

• Larger doors for easier access to interior elements including coil–nail spools

Terminailer is an event-driven, sub-component assembler that will quickly and accurately drive 30% to 70% of the framing nails in any wall panel job. In your shop or in the field, one operator sets the pace for production and quality. The Terminailer functions independent of design software, requires zero set-up time when switching between any configuration, and requires no special operator training.

The Terminailer is easy to move around the shop so its location can evolve as your shop evolves. With all of the nailing occurring in the closed main chamber, nail injuries and nail location misfires are eliminated, making your plant that much safer.

With nearly ten years of development from people that know machinery, it is assembled to exacting standards, well supported, and it is easily maintained with shelf-item parts. Terminailer: vetted, tested, and ready to drive maximum productivity for you. Be sure to check out our videos below for a quick review of this revolutionary machine!

240 volt, 1-phase, 30 (full load) Amps, 60 Hz electrical required. 50 SCFM @ 120 PSI air required. Net weight 7,000 lbs.

Layout: Terminailer V.8 Layout

Nailing Configurations: Terminailer V.8 Configurations