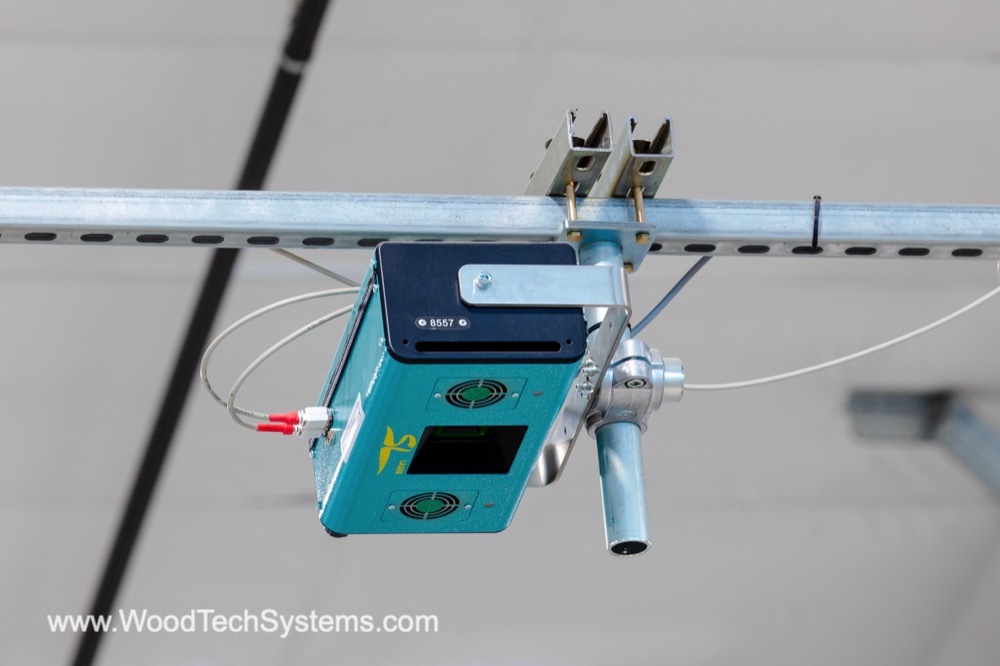

SL-Laser

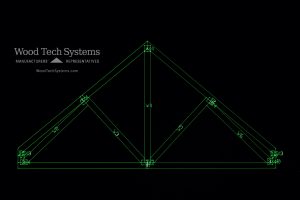

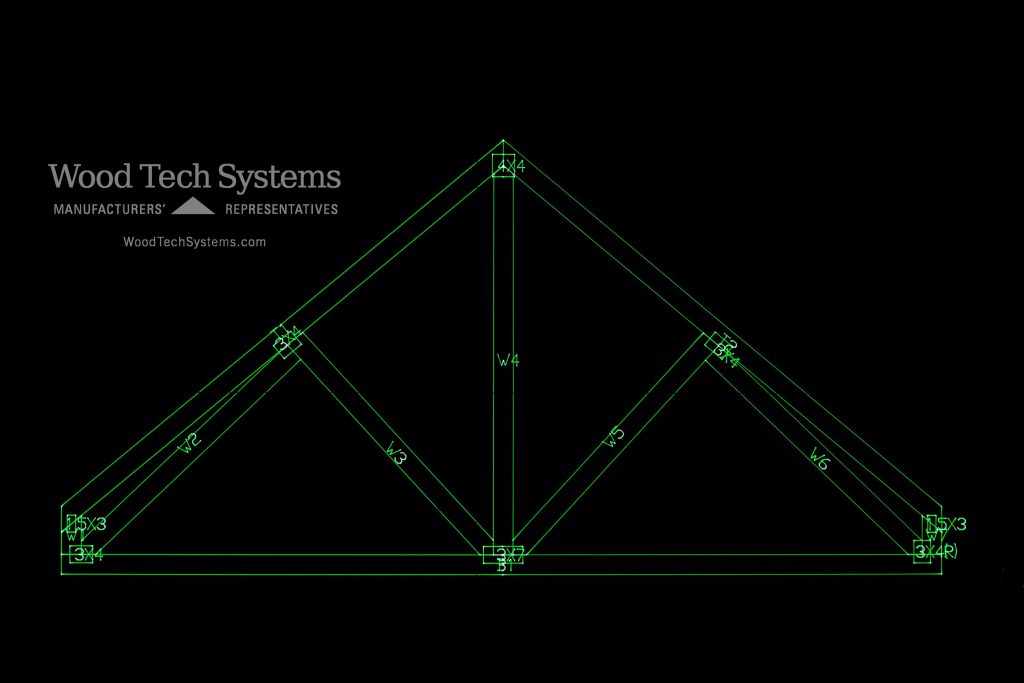

When building roof trusses (wall panels, floor trusses, or floor panels too), complicated setups compound labor costs and affect your bottom line. With a Truss Projection System from SL-Laser, every setup is simplified with laser light templates. An accurate, full-scale 1:1 image of each truss is projected on the table to set chords, webs, and nail plates in sequence.

Each truss can be jigged in minutes, shaving as much as 70% off your setup times. The more frequent the setup changes, the more labor savings you’ll realize with a laser projection system. From simple to the most complex truss, each setup is just as easy when you’re just placing lumber to the green laser lines. No more labor standing around while the lead man figures out the setup. Anyone can follow the laser template – even new, unskilled, or foreign-language workers.

Improved quality is a byproduct of the efficiency you’ll gain with a truss projection system. Not only will you build tighter, more consistent trusses, you’ll also get exact plate size and location. No more oversizing plates to compensate for sloppy, guesswork placement.

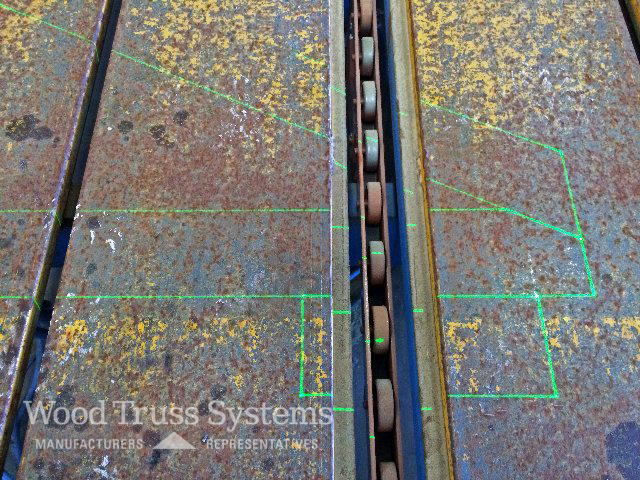

With SL-Laser, you are dealing with the team that installs and serves what they sell from their USA Headquarters in Charlotte, NC. Please Note: When compared to the competition, SL is missing several items. One thing SL doesn’t have are costly (and ridiculous) annual maintenance agreements. They also don’t charge you to replace a projector when a simple, self-installed part will do the job. Oh, they also don’t make you pay to talk to them; they figure customers are supposed to ask their supplier questions and for advice.

Save labor cost, increase production capacity, and improve quality – all in an easy to use package backed by over 20 years of experience industry!

Description

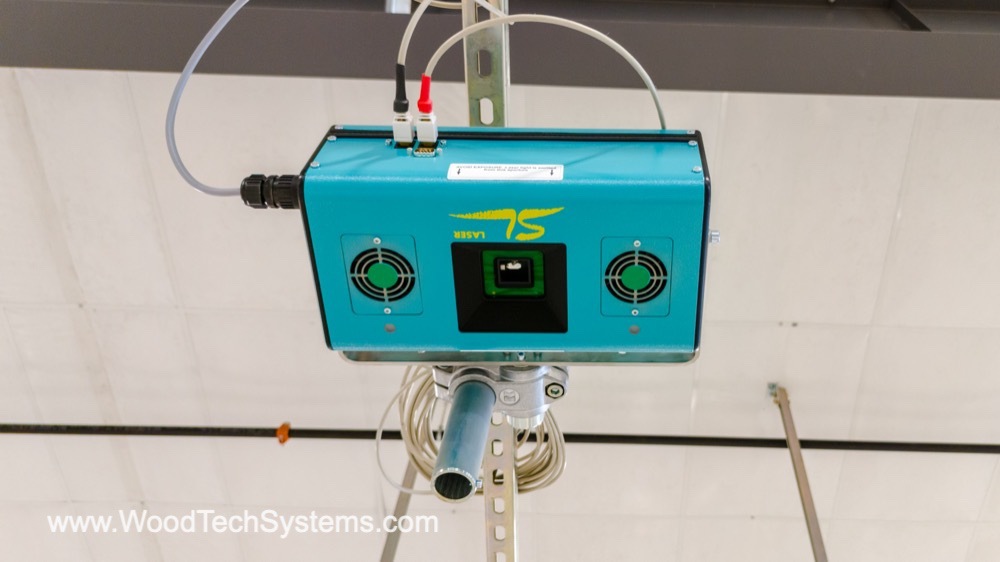

Innovative laser technology saves time and improves quality in producing roof truss, wall panel, and floor panel elements. SL-Laser combines technical ingenuity and years of component industry experience to deliver a package that provides easily measurable savings. Setup times are dramatically reduced, production processes are simplified, and quality is improved. Easy to control and virtually maintenance-free devices ensure the safe flow of your production and have a fast return on investment.

References

Wood Truss Systems has sold laser projection systems to the wood component industry for over 20 years, dating back to the pioneering truss company who started it all in Maple, Ontario. We are big believers in Laser projection and have sold systems new and used throughout the USA, Canada, as well as systems in Australia, and China. Having sold for the two suppliers in our industry we can easily say with that SL-Laser is the best when it comes to customer support and service; they are also the most economical to operate over the life of the system. SL-Laser USA brings world class technology to our industry, simply second to none.

Joe Halteman – Laser Specialist: (765) 748-0332

Jay Halteman: (765) 751-9990

Jim Mavrakes: (817) 291-4999