The new Hain Sub Component Nailer (SCN 6) substantially speeds the cumbersome task of building wall panel sub-components like trimmers (built two at a time), stud-block-stud channels and variations of preassembled framing sub-components.

The SCN 6 has no length limitations works well in “Just-In-Time” or “batch” production. The SCN 6 setup is instant: from chosen configuration to chosen configuration instantly, using the analog machine multiple position switch, with (8) common configurations from corners, channels, trimmers, and other configuration desired within those 8 parameters. The SCN 6 is fully enclosed for safety, is easy to maintain, and loading nail guns is simple and convenient for the operator.

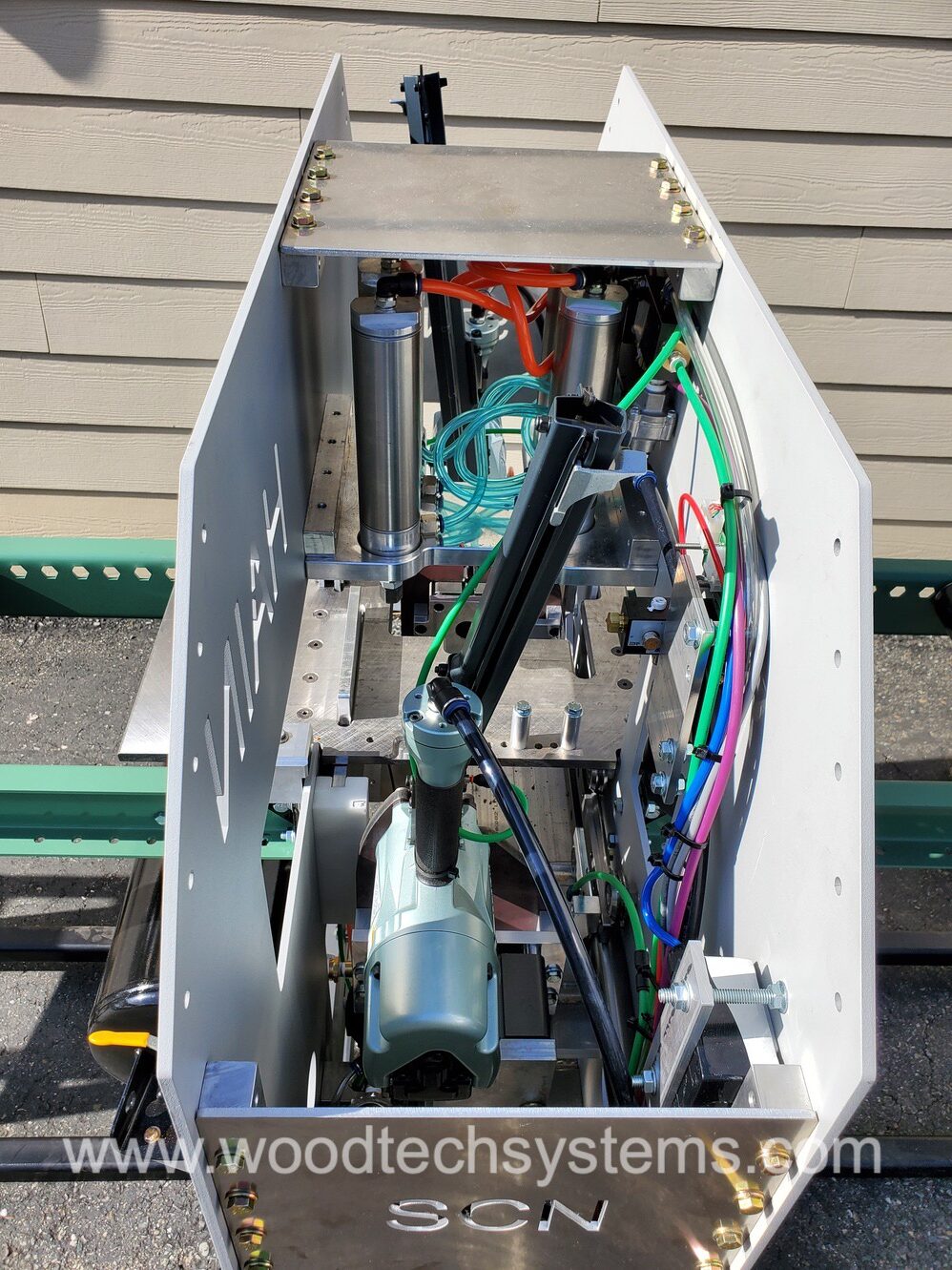

The SCN 6 is CAD/CAM designed, efficiently built using a modern CNC machining center to machine aircraft-quality 6061 billet aluminum stock for all internal parts. External outside frame is CAD/CAM designed, laser cut 1/4” steel main frame plates, powder coated and assembled with grade 8 fasteners throughout. All of this make the SCN 6 robust, simple, dependable and productive. The SCN 6 control is simple with advanced pneumatic circuitry that is intuitive, robust, easy to troubleshoot and maintain.

The SCN 6 can place (2) nails in a 2×4, (2) or (3) nails in a 2×6, or stagger the nail pattern all with just a turn of a switch.

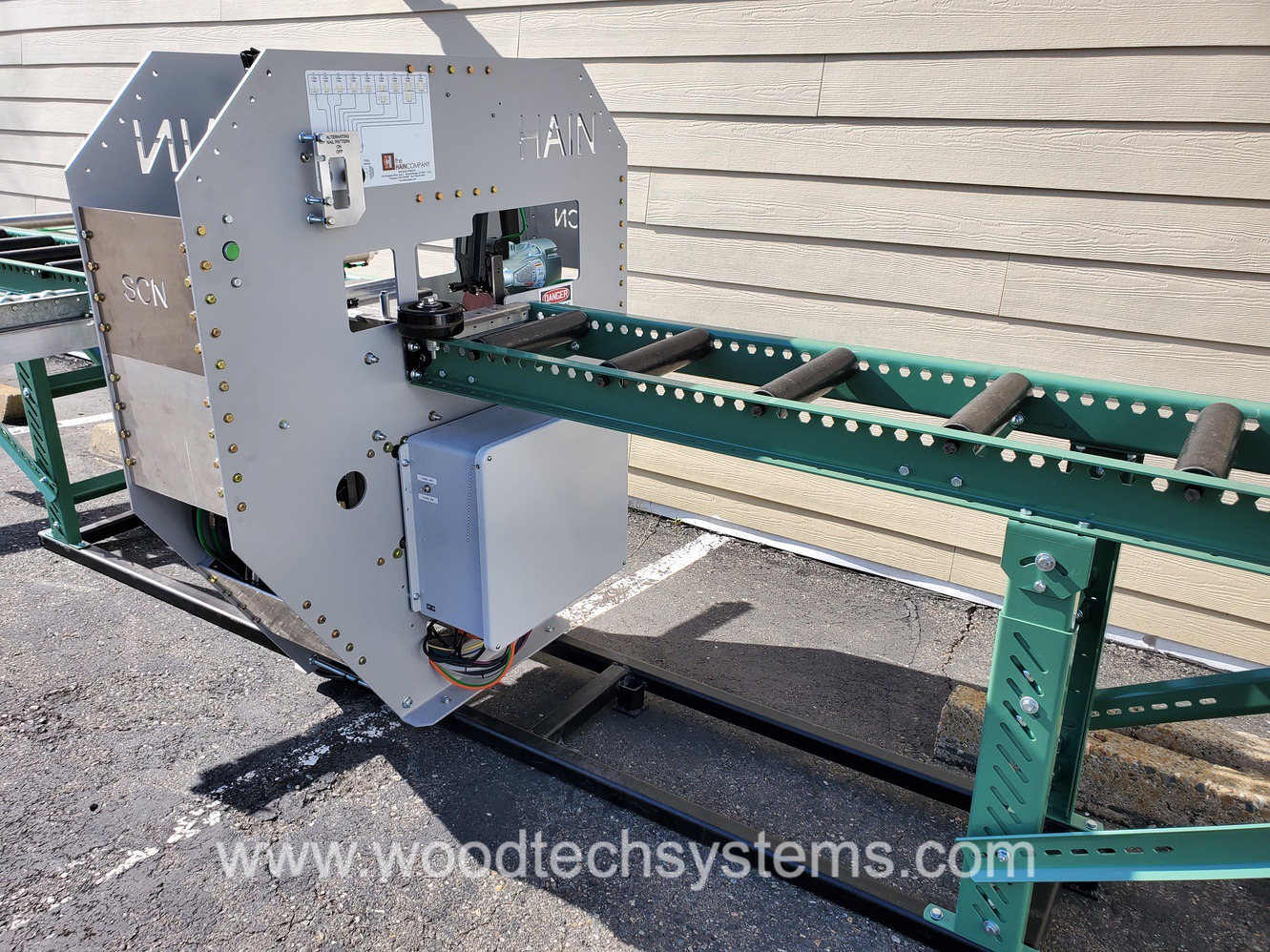

The SCN 6 comes with Heavy Duty one 10-foot roller bed infeed, with a board guide. The outfeed is a Heavy Duty 10-foot roller bed with a 5-foot side-discharge roller transfer system. The SCN 6 has a board bump stop used when loading component boards to the stop, after the first nail cycle the stop retracts automatically to facilitate advancement of component, and when the component is fully nailed and exits The SCN 6. The stop retracts automatically and the finished component is automatically transferred to the transfer roller.

The SCN 6 is skid-mounted to facilitate a plug-and-play installation, or to be easily moved to various locations in the shop. Plug it in to a wall circuit and a compressed air supply and play.

Block Sizes: 2×4 & 2×6 Standard Framing lumber any length

Nail Cycle Time: 1 nail cycle time 1 second, 2 nail cycle time 2 seconds, 3 nail cycle time 3 seconds

Machine set up time: 1 second from any prior set up

Air Supply: 125 psi at 30 CFM nothing less at the guns between nailing cycles 125 lbs for clamping, 40 to 50 PSI for control

Clamping pressure: 5 top board clamps 500 lbs each, 2 side board clamping 500 lbs each total clamping pressure 3500 lbs.

Electrical Supply: 120 VAC standard 15 amp U ground plug installation is plug and play

Frame: 2 each ¼” thick laser cut CNC formed 1018 steel plates powder coated no welds

Covers: ¼” 6061 CNC machined aluminum

Dimensions: Length SCN 6 21 feet long skid mounted shipping length 10 feet X 9 feet X 5 feet

The SCN 6 machine head is 48”X12”X 48”

Shipping weight: 1600 lbs. – shipped open skid with protection on the SCN 6 machine head.